IBM Selectric Typewriter Resource Page

Michael A. Covington

I've owned a Selectric II typewriter since 1975 and still use it to type labels

and forms. Although most of my writing has been done with computers since 1985

or so, the need to make legible marks on pre-existing pieces of paper has never

gone away, so along with my keen interest in fountain

pens, I've taken up the cause of keeping alive one of the finest typewriters

ever built.

In fact, in 2009 I succumbed to the temptation to buy a second Selectric II, for use

in my home office, and this one has all the features I really wanted the first time:

dual pitch, 1.5-line spacing, and most importantly, correcting.

Other middle-aged men waste money buying a car just like their first one;

this is cheaper.

Note: I do not sell or repair typewriters. Check advertisers and

links on this page to find those who do.

Contents:

Introduction

Useful links

Why I like a Selectric

Selectric lineage (product lines)

Misuse of the name

Ribbon options

Correcting and lift-off options

Where to find a used Selectric

How to ship a Selectric

How to check out a used Selectric for proper operation

Wrong characters print occasionally

Keys stick down (don't come back up) after typing

The IBM Selectric Typewriter,

introduced in 1961, is one of the most

important mechanical inventions of the Twentieth Century.

It is, indeed, all mechanical; an electric motor is used only to turn one shaft,

and its function can be taken over by a hand crank (and is, during repair procedures).

It may be the last major invention that doesn't use any form of electrical control.

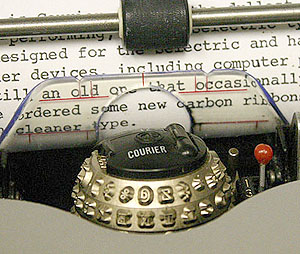

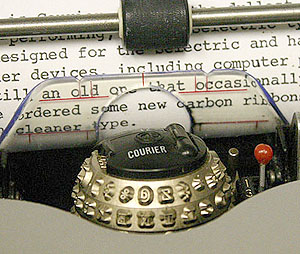

This is the "golfball" typewriter, the one whose type is on an

interchangeable element (ball)

rather than on individual levers. A close imitation, the Sperry Remington SR-101, was made by

by Remington

the late 1970s after IBM's patent expired, and its type elements are interchangeable

with IBM's. (The machine was reportedly unreliable,

and the manufacturing arrangements fell

apart in lawsuits.)

Also, in the 1980s, GP Technologies (now out of business) made a wide variety of specialty

type elements for Selectrics; in place of the IBM logo they have a round seal with "GP" in

the middle of the lever.

Contrary to what is widely thought, the Selectric did not originate as a computer

terminal, and typing is not an electrically controlled process.

But it is computational.

Each key triggers a set of tabs representing a binary number, which

is the input to a mechanical digital-to-analog converter which turns the type

element to the right position.

When computer terminals were later built using the Selectric mechanism, the keyboard

and the rest of the typewriter had to be separated. The keyboard was replaced by

a set of switches, feeding a set of solenoids to play the role of the original keys.

The whole thing also had to be ruggedized because a computer terminal undergoes much

heavier use, with constant typing at high speed, than an office typewriter.

Useful links:

These links were correct when this page was created.

This page is not maintained and the links will become out of date.

Please use search engines to find current information.

Typewriters.com, a major repairer and reseller of Selectric

and other typewriters. (Hint: Their refurbished typewriters cost a good bit less if you are

willing to pick them up in Decatur, Georgia, rather than having them shipped.)

www.selectric.org: scans of instruction manuals and other information

www.mortonsweb.com: Selectric repair manuals

www.etypewriters.com/history.htm: history of IBM typewriters

Wikipedia articles:

IBM Selectric Typewriter,

Courier (typeface),

Prestige Elite (typeface),

Letter Gothic (typeface).

Yahoo Group Golfballtypewritershop (Selectric maintenance and repair).

Why I like a Selectric: Besides reliability, versatility,

and high print quality, the

Selectric is fast. Recently I tried out a modern low-end daisywheel typewriter,

and it was like typing through a time warp — the letters were appearing on

paper much more slowly than I was hitting keys, and by the end of the line, there

was a quite noticeable delay. Because the daisywheel typewriter stores keystrokes,

of course it never lost anything, but I also couldn't see, in real time, where letters

would appear on paper.

The inherent speed of the Selectric is more than 15 characters per second, and it has one keystroke

of mechanical "stroke storage." That is, if you hit two keys very close together, the first

one and the second one will both actuate, each in due time. This is accomplished by having each

key release an "interposer," which is allowed to go down when the mechanism is ready

for it. The interposer is the component with binary-coded tabs on it that I mentioned earlier.

If more than two interposers go down at the same time, you have a slight risk of a jam,

which can be cleared by pressing Mar Rel. But few typists are that clumsy.

The force required by each Selectric key is about two ounces (30 g) to actuate it, and about

half that to keep it down after it has actuated. That is more than most computer keyboards

but less than other electric typewriters. The keyboard "touch" of the Selectric is not adjustable.

The January 1968 issue of IBM Journal of Research and Development is devoted to the

Selectric Composer and includes a lot of information also relevant to Selectric typewriters.

Selectric lineage: The main products in the Selectric product line are:

-

Original Selectric family:

These take 88-character type elements, which have white labeling and may have "72" (never "96")

written on them. These are the most widely used Selectrics.

- Selectric

model 71 and 72 (later called "Selectric I") — rounded body. Each of these

is fixed at either 10 or 12 pitch.

- Selectric II (with or without correcting feature), which may be 10 pitch, 12 pitch, or dual

pitch. This is the most popular Selectric, and many consider it the most reliable.

- The IBM Personal Typewriter, mass-marketed in the 1980s, perhaps to use up IBM's stock

of Selectric II parts. It is basically a small, slightly simplified Correcting Selectric II

that takes the Selectric III "bicycle" ribbon. Not to be confused with the Personal Wheelwriter,

a daisywheel typewriter that came later.

-

Selectric III family:

These take 96-character type elements that have yellow lettering and almost always have "96"

written on them. The move to 96 characters was prompted by the need for a larger character set on

European typewriters. Many Selectric IIIs have keys for only 92 of the 96 characters.

- Selectric 96 (marketed overseas).

- Selectric III, very similar to the Correcting Selectric II but redesigned.

- Various IBM Electronic Typewriters which take Selectric III elements and also similar-looking elements

with proportional pitch.

-

Others:

- IBM Selectric Composer,

a proportional-pitch typesetting machine whose type elements are

coded with yellow, red, or blue triangles.

- Various IBM computer terminals

with Selectric-style elements that may or may not be

compatible with Selectric typewriters.

- The name Selectric System/2000 was used briefly in the 1980s for a family of letter-quality printers

and typewriters including the Quietwriter. These do not use ball-shaped Selectric elements at all.

Misuse of the name: Some people think "Selectric" means "electric typewriter."

You will occasionally see ads, particularly on Craigslist, where this has been misunderstood.

"Selectric" is legitimately the name of some products that have nothing to do with typewriters,

including a type of boat motor and a type of sawmill.

The Selectric was not the only IBM electric typewriter. IBM made conventional electric typewriters

from early times well into the 1960s if not later. Back in the 1950s, they were remarkably ugly

(looking like gray boulders)

but performed well and were very popular. The IBM Executive Typewriter

was a conventional (typebar) typewriter with a carbon ribbon (for sharp print) and proportional pitch.

Ads on eBay are often mistaken as to the exact features of the typewriter.

A full-featured Selectric II or III (dual pitch) has six bright chrome levers

coming up through the case, three at each end of the platen roller.

Ribbon options: In the public eye, the Selectric typewriter was largely equated with

the crisp black print of a carbon ribbon, but that is actually a mistake.

IBM and other brands of electric typewriters offered carbon ribbons long before the

Selectric came out. But fabric ribbons were an option for all three models of Selectric.

Even with a fabric ribbon, the Selectric produces clearer print than most fabric-ribbon

typewriters.

It is best to look at a Selectric typewriter and see what kind of ribbon it uses

rather than guessing. The original Selectric came in two models; one takes a carbon ribbon on

reels, and the other takes a fabric ribbon in a cartridge.

The Selectric II normally takes either of two kinds of ribbon cartridges, Correctable Film or Tech III

(both fit on the same typewriters).

The Correctable Film Ribbon (yellow or orange color-coded)

gives a very sharp, carbon-ribbon-style image; the Tech III (blue color-coded, no longer

made) is a thin fabric ribbon that gives near-carbon quality. Corresponding to each of these is

a type of correction tape with the same color code, Lift-Off Tape or Cover-Up Tape.

There is also a (carbon) cartridge ribbon for the Selectric Composer that will fit the Selectric II.

It is color-coded green and produces very crisp, high-quality type, but does not "lift off."

That means it can be used safely to type checks.

However, some Selectric IIs were made with the Selectric I fabric ribbon system.

With the Selectric III, the situation is even more complex. The usual ribbon is a cartridge

that works like that in the Selectric II but has a different shape, somewhat like a bicycle in

side view. However, some Selectric IIIs take the Selectric II ribbon cartridges, and a few take the

Selectric I fabric ribbon.

Why were fabric ribbons offered? For two reasons: economy and security. They are of course cheap.

There are also two security factors. With any type of carbon ribbon, you can discover what has been

typed by reading the letters off the used ribbon, because the carbon ribbon only makes one pass through

the print head. Also, carbon-ribbon ink can be lifted off the paper (that's how the Correcting Selectric II

and III make corrections). For those reasons, fabric ribbons are preferred for bank documents and

confidential data.

Correcting and lift-off options:

The traditional late-1970s way to make corrections when typing was to use Ko-Rec-Type,

a material like carbon paper, but white. You would hold a piece of Ko-Rec-Type between

the typewriter mechanism and the paper, and restrike the incorrect letter, depositing white

pigment on top of it. This worked with any kind of typewriter.

The Correcting Selectric introduced lift-off tape, which would actually remove carbon-ribbon

ink from paper. Soon afterward (when Sperry Remington came out with their Selectric clone that

lacked the correcting feature), lift-off tape became available in 1-by-2-inch tabs like Ko-Rec-Type.

As far as I know, it is no longer made, but you can buy a roll of lift-off tape (any brand) and

cut it into small pieces for handheld use.

Lift-off tape works well if you are typing on smooth paper. With cheap laser printer paper,

a lift-off correction may take several tries.

With Tech III ribbons you can't use lift-off tape. Instead, IBM made

cover-up tape (color-coded blue like the ribbons), which worked like Ko-Rec-Type.

It is no longer made but can still be obtained from some suppliers.

As far as I can determine, current Brother typewriter lift-off and cover-up tape fit the Correcting

Selectric II and III. So this is the one Selectric consumable supply that is not at all

obsolescent.

Where to find a used Selectric:

One option is to buy a reconditioned one, with warranty, from a refurbisher;

several of them advertise on eBay and

other places. The other option is to find a Selectric in used condition and then

have it cleaned, lubricated, and repaired as needed.

Ideally, you want an individual's personal typewriter rather than one that

was used in an office. The reason is that office typewriters are often

worn out. The Selectric was designed to last 8 years being used 8 hours a day

every business day (about 16,000 hours of total use). An individual who

was not a typist would typically use it a lot less.

It is best to find one locally via Craigslist

or by asking around, because it won't have to be shipped, and you can inspect it before

making the purchase. Also, it may be very cheap, especially if you ask your network of friends

whether anyone has a no-longer-needed typewriter in the closet.

How to ship a Selectric: The best way to pack a Selectric for shipment is

to fill plastic bags with expanding, hardening foam (a familiar procedure at places

that offer professional packing). Keep it right side up at all times during

shipment because older Selectrics, if inverted, are likely to break loose from the bottom of the case,

causing damage.

How to check out a used Selectric: I assume you have read the instruction manual

and know the basic functions. Note that the ribbon is likely to be in poor condition,

so make allowance for it or bring a new ribbon.

(1) Turn the typewriter on. If the keyboard is locked, make sure the on-off

switch is all the way to on, and press Mar Rel. If that unlocks the keyboard and it

doesn't lock again, you're OK.

(2) Listen. A running Selectric should produce only a low hum. If there is a

click-click-click sound, there's likely to be

a crack in the main sprocket,

which is difficult to replace, and your Selectric is not long for this world.

However, there are also other sources of click-click-click sounds.

(3) Type every key, both shifted and unshifted, and make sure the right character

prints. (Some type elements have characters in different positions than others; make sure

you get results that are correct for the element you are using.) If there are problems,

check whether the element has any of its teeth broken off along the bottom edge,

and if so, substitute a good element and check again.

(3a) Hold down the hyphen key (-) and type a series of hyphens to make sure they

all strike correctly. This is a very stiff test

of internal adjustment; it is also a stiff test of the type element, and worn or non-IBM

elements often fail it. If you find a problem, definitely try changing elements.

(4) Check for proper operation of Return, Exp, Index, and Tab, and check whether the keys

come back up properly after you release them. At this point you are checking for cleaning

and lubrication problems.

(5) Type a page or two, fairly fast,

and observe performance. It is likely to get better after you've

typed for a few minutes, making sure to use every key several times.

(Type "The quick brown fox jumped over the lazy dog.")

Check other functions based on the instruction book.

Note: Any typewriter that has not been cleaned and lubricated for 15 years or more

will need maintenance. No matter how pristinely preserved, a vintage Selectric that has

never been to the shop will not be ready to use today. On the other hand, a typewriter that

has been under a maintenance contract may not be a good buy — it may be worn out by

the time it gets to you.

Wrong characters print occasionally: This can be an adjustment problem, but it can

also be a sign of a slightly-out-of-spec type element. I have many GP Technologies type

elements on which any attempt to auto-repeat the hyphen key (type ---------- by holding

the key down) produces a mishmash of misstruck characters. With IBM type elements in the

same typewriter, there is no problem.

If wrong characters print consistently, look for teeth broken off the bottom edge of the

type element.

Keys stick down (do not come back up) after typing:

If some keys type normally, but are slow to come back up after typing, this is probably

a lubrication problem, easy to fix. It is most common with the keys that are least often

struck, such as X, Z, and 1. The exact symptom is that although the key is slow to come back

up on its own, if you pull it up you can type it again without any problem.

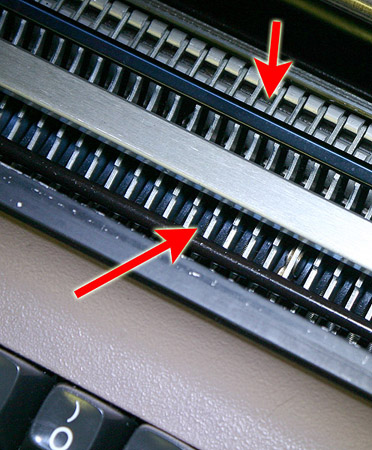

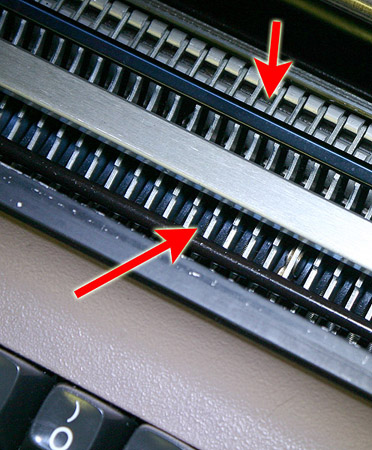

To fix it, you may not even have to remove the cover; just flip

it up as if you were going to change ribbons. You'll see that each key presses

a bar down. The picture shows the lubrication

points.

At the upper lubrication point, the bar pivots in a slot;

at the lower one, it rubs against, and bends, a leaf spring whose

job is to push it back up again.

Do not spray WD-40 or similar substances into the typewriter

because there are components that can be harmed by the spray.

Instead, first use a can of compressed gas ("Dust-Off" or equivalent) to

make sure there is no trash causing the bar to stick. Then apply tiny droplets

of penetrating oil at the lubrication points, and type the key several times.

Use a very light oil. Many kinds work well, but I have two favorites.

One is Marvel Mystery Oil, which is a mixture of a light oil and a solvent;

I have no idea whether it is good for car engines, but it is the recommended

lubricant and cleaner for some tools and other small machines.

Another is Mobil 1 Synthetic Motor Oil, grade 0W-20 (super-light).

This is an exceptionally effective lubricant and penetrant, and I use it as

a superior replacement for 3-in-1 and other general-purpose light oils.

Be sure to apply no more oil than necessary so that the oil itself

doesn't cause sticking.

NOTE: The material above has not been updated since 2009.

However, Peter Simpson has sent along the following updates, for which I thank him:

One good place to find used Selectrics is: shopgoodwill.com

Cracked power sprocket: there are two metal replacements available through eBay, one machined and one 3D printed. They come highly recommended.

The hand cycle tool (with its wonky left-hand thread) is available on eBay.

Phoenix Typewriter videos on Youtube will help you diagnose and repair common problems.

There's a Yahoo and Facebook group: golfballtypewriters

Recommended lubricants:

IBM #10 oil = 0W30 Mobil 1 synthetic oil

IBM #23 grease = Mobilgrease #28 Aero Grease

PBBlaster penetrating oil works well to loosen gummed mechanisms (avoid WD-40, because it leaves a waxy deposit).

Rather than lacquer thinner (which eats Selectric II keytops) use mineral spirits to loosen gummy grease — also cleans platens.

IBM Service Manual PDF is here: https://www.scribd.com/document/372545238/ibm-selectric-service-manual-a

IBM Adjustment Parts Manual (1980): https://www.marklin-users.net/cookee_nz/hobbies/IBM/IBMSelectricAPM-Nov1980.pdf

I am not responsible for these links and cannot guarantee that they will remain active or appropriate.

|